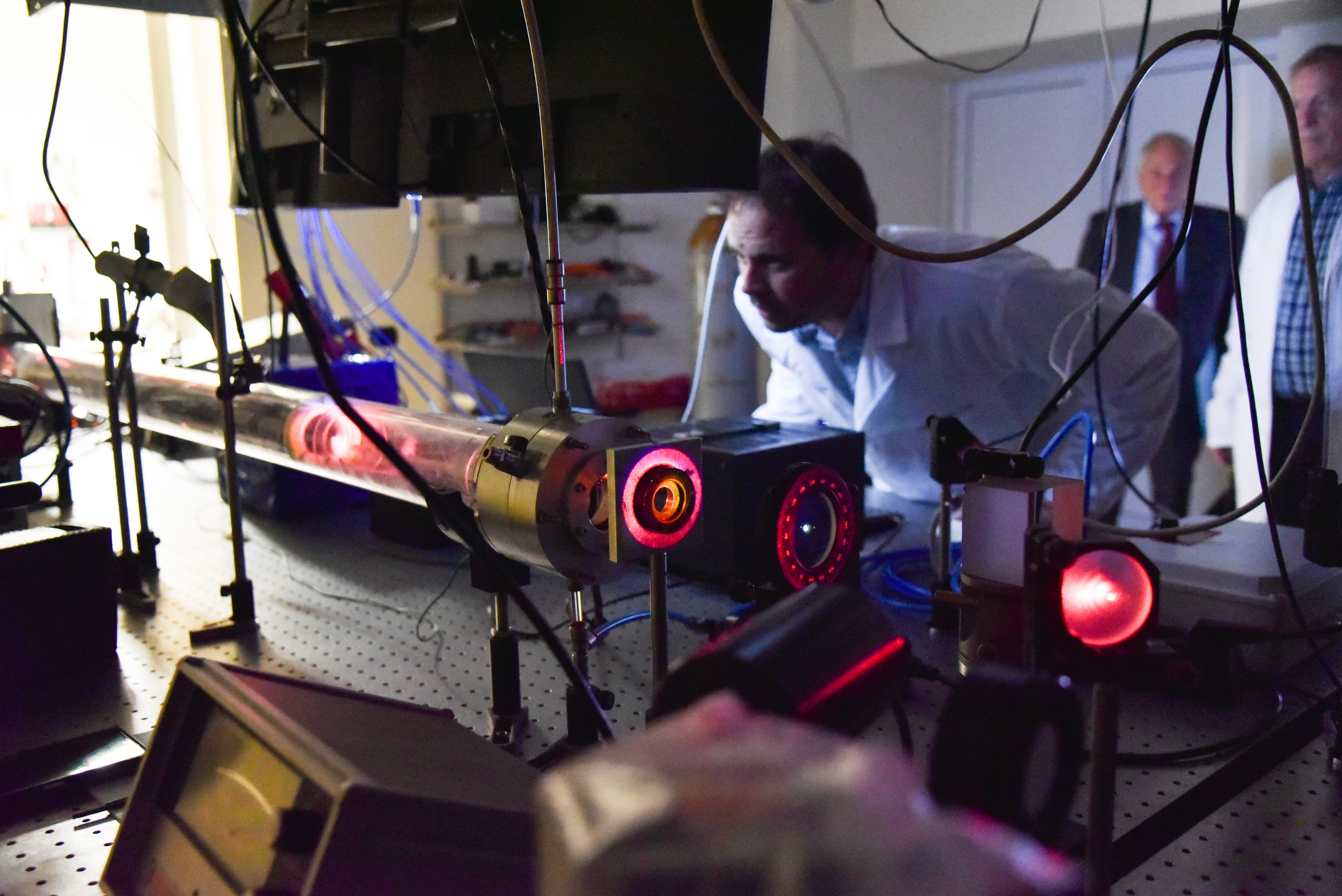

Innovative surface coatings with potential for wide application in the field of mechanical engineering and high technology are being developed by scientists from the Institute of Electronics of BAS. Researchers have improved the mechanical properties of surface structures made of titanium with boron and carbon added to it. The resulting new coatings have very high surface hardness values as well as high wear resistance which opens up a range of new practical applications for these materials.

The development is part of the “Centre of Competence for Intelligent Mechatronic, Eco- and Energy-Saving Systems and Technologies” project which involves a team from the Institute of Electronics. The researchers have also developed a new high-strength and ductile weld joint between an aluminium and titanium alloy – a breakthrough that has not been described in scientific literature before. The innovation opens up new horizons for applications in automotive, aviation and aerospace technologies.

The second phase of the “Centre of Competence for Intelligent Mechatronic, Eco- and Energy-Saving Systems and Technologies” project was launched at the end of September. The lead organisation is the Technical University of Gabrovo. Upcoming tasks for the team of the Institute of Electronics are related to the development of welding seams with introduced alloying elements as well as surface modification of titanium and aluminium alloys by means of intense energy flows.