The successful implementation of the project “Estimated Analysis of the Resources in the Reactor Hulls of Units 5 and 6 of Kozloduy NPP based on the results of testing and examination of witness samples” was completed. Determination of activities and neutron fluence of witness samples from 3L assembly of Unit 5 and 2L of Unit 6 of Kozloduy NPP. The results of the project were directly related to the extension of the service lifetime of the reactors in the plant. The research was conducted under a contract between the Institute of Metal Science, Equipment and Technologies with the Center of Hydro- and Aerodynamics “Acad. A. Balevski “- BAS and Kozloduy NPP plc.

The aim of the project was to determine the change in metal properties of the reactor hulls of 5 and 6 Power Units under the influence of radiation and thermal impact at the time of the removal of the samples from the reactors.

The obtained experimental and estimated data are used in procedures for assessing the possibilities for extension of the design service life of Kozloduy NPP 5th and 6th Power Units.

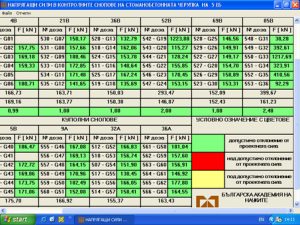

In recent years, scientists and highly qualified specialists from the Institute of Metal Science, Equipment and Technologies with the Center for Hydro- and Aerodynamics “Acad. A. Balevski “- BAS fully designed and implemented a system for monitoring the stressed state of the Kozloduy NPP reactors’ protective shell. Safety element of the WWER 1000 type reactors of Kozloduy NPP is the reinforced concrete protective shell which is subject to independent state and international surveillance. In order to control the reliability of the protective shells, the Institute’s team has implemented an original methodology for controlling the stressed state of shells by measuring the strain strength of anchors.

A system for automatic control of the strain forces in the bundles has been designed and built which uses tension force transducers to measure tension in a number of threads. Their state is recorded in a database and, according to a certain algorithm, the stressed state of the protective shell is evaluated and visualized. The results of the force measurements in the threads are presented in tabular and graphical form.

During yearly scheduled repairs at Kozloduy NPP, an inspection was carried out of the system for monitoring the stressed state of the protective shell of the WWER 1000 reactors.

During inspections by teams of the International Atomic Energy Agency, the World Association of Nuclear Operators (WANO) and the Atomic Questions Group of the Council of the European Union etc., the safety of the protective shells has received high praise and international recognition.